China’s manufacturing landscape is undergoing a major shift as smart factories powered by AI, automation, and digital systems reshape production.

Bright lights flood the workshop. Robots glide smoothly along the production line, coordinating with human workers. Every few seconds, a new electric vehicle rolls off the line, while sensors and screens track every process. This is not a futuristic concept — it is the daily reality in China’s growing network of smart factories.

Across the country, traditional manufacturing floors are transforming. Digital systems, artificial intelligence, and industrial automation are now central to production, turning once isolated pilot projects into fully operational, high-efficiency factories. These developments are reshaping how China builds cars, electronics, and advanced materials — and offering a glimpse of what the future of manufacturing could look like worldwide.

A Multi-Tier Smart Factory System

China has built a layered smart factory system rather than relying on scattered trials. By 2025, more than 35,000 basic-tier smart factories were operating nationwide. They are supported by over 8,200 advanced-tier facilities, more than 500 excellence-tier smart factories, and 15 classified as leading-tier smart factories. Together, they form a pyramid structure that allows smart manufacturing to scale from mass adoption to global benchmarks.

At the same time, manufacturing continues to anchor the broader economy. In 2025, China’s value-added industrial output expanded 5.9 per cent year on year. Manufacturing maintained a stable share of GDP and is expected to remain the world’s largest manufacturing base for the 16th consecutive year.

More importantly, digital transformation is moving beyond individual factories. As a result, new technologies are shifting more quickly from testing to large-scale industrial use.

AI Redefines the Factory Floor

One of the clearest changes inside smart factories is the expanding role of artificial intelligence. AI is no longer limited to automation or visual inspection. It is increasingly embedded in production decisions.

According to industry data, AI now covers more than 70 per cent of business scenarios in leading smart factories. It supports the large-scale deployment of industrial software and intelligent equipment, forming early versions of “emerging industrial agents” that can sense conditions, make judgments, and execute actions.

As a result, manufacturing is moving from automated systems toward more autonomous ones. Production lines can now detect problems, adjust processes, and improve performance through continuous data learning.

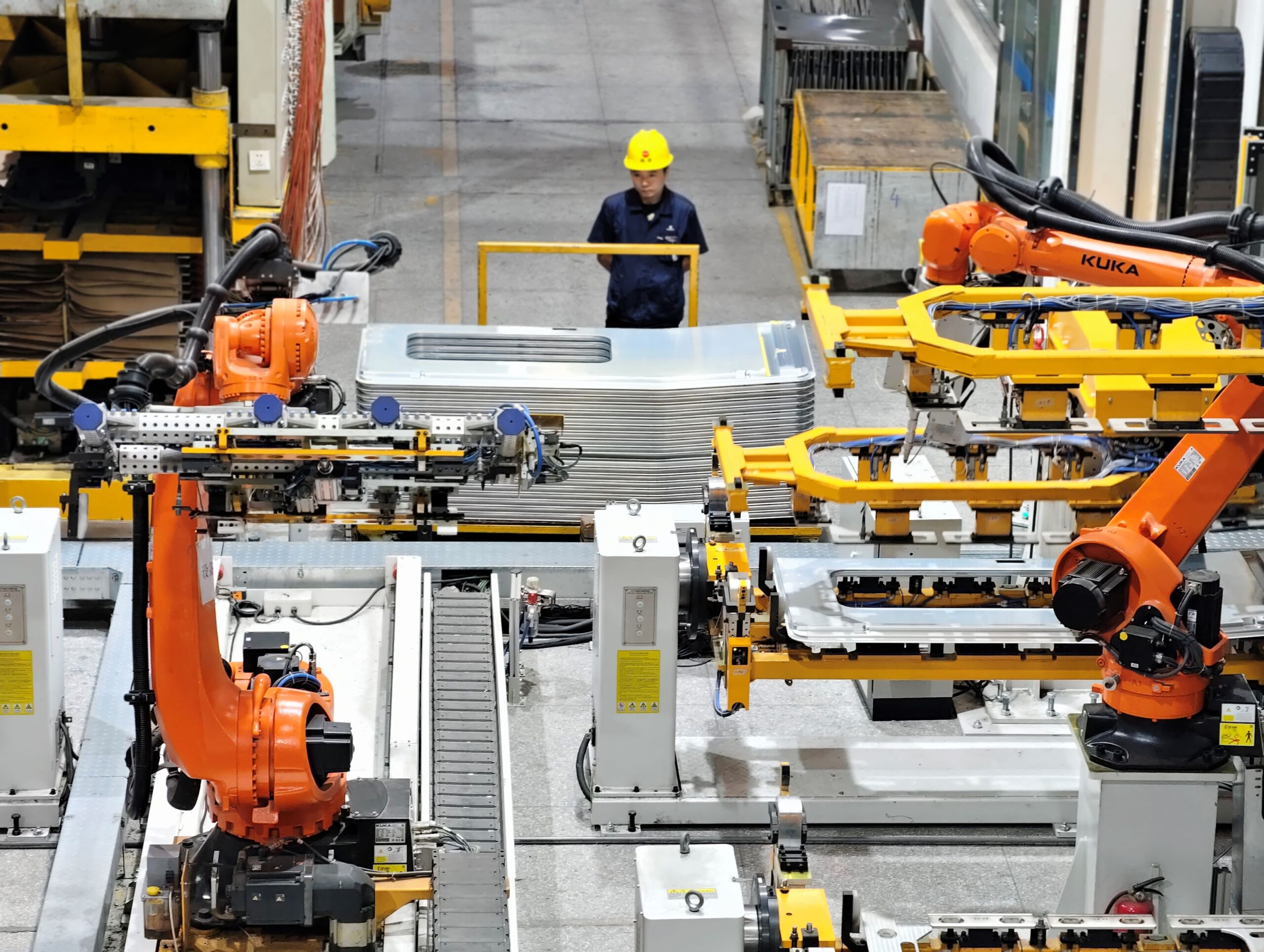

Inside China’s Smart Factories

At Xiaomi’s electric vehicle factory in Beijing, more than 700 robots operate across the production floor. A new vehicle rolls off the line every 76 seconds. Key processes are fully automated, while more than 200 critical steps are numerically controlled. Assembly errors are reduced to fractions of a millimetre.

A massive die-casting machine weighing 718 tons sits at the centre of the operation. Working with over 60 connected devices, it compresses 72 components into a single part. As a result, production time for those processes has been cut by nearly 74 per cent. The gain comes not only from speed, but from redesigned manufacturing logic.

AI also plays a central role in quality control. Xiaomi’s self-developed “X-Eye” inspection system replaces manual checks and achieves an accuracy rate above 99.9 per cent.

A similar model is evident at Li Auto’s green manufacturing base in Beijing. Its in-house manufacturing operating system connects logistics, assembly, and quality management. Automated guided vehicles and robotic arms handle tasks such as picking, welding, and tightening. When quality issues appear, the system flags them instantly. Over time, the production line improves through accumulated data and feedback.

Smart factories are rapidly becoming standard practice across China’s electric vehicle sector. They are also accelerating the industry’s shift toward electrification, intelligence, and greener production.

Meanwhile, global benchmarks are taking root. In Shanghai, Schneider Electric’s Shanghai Putuo factory has been recognised by the World Economic Forum as an “end-to-end lighthouse factory.” Despite its modest size — about 11,000 square meters and 500 employees — the plant achieves high efficiency through digital systems and flexible, modular production lines. These lines adapt quickly to changing customer demand while reducing energy use and time to market.

During the current five-year planning period, Shanghai has added several lighthouse factories and rolled out more than 1,000 smart manufacturing scenarios. Together, they show how international standards and local industrial ecosystems are increasingly aligned.

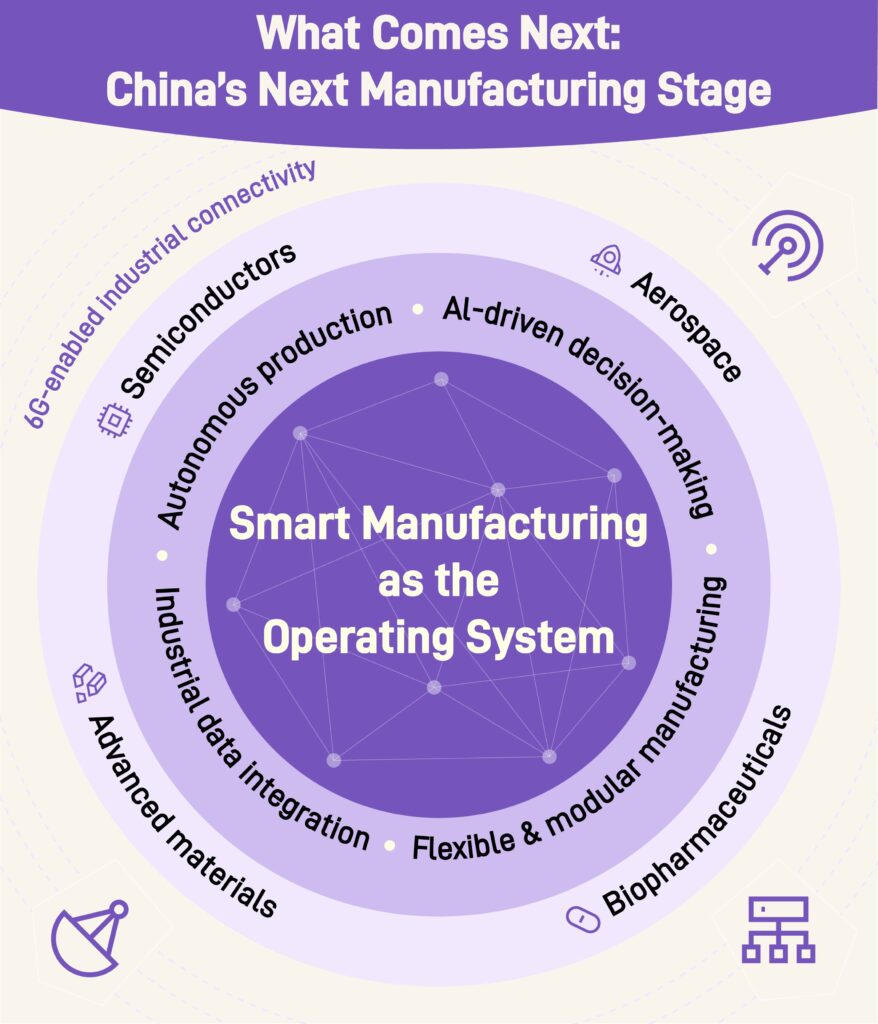

The Next Phase of Manufacturing

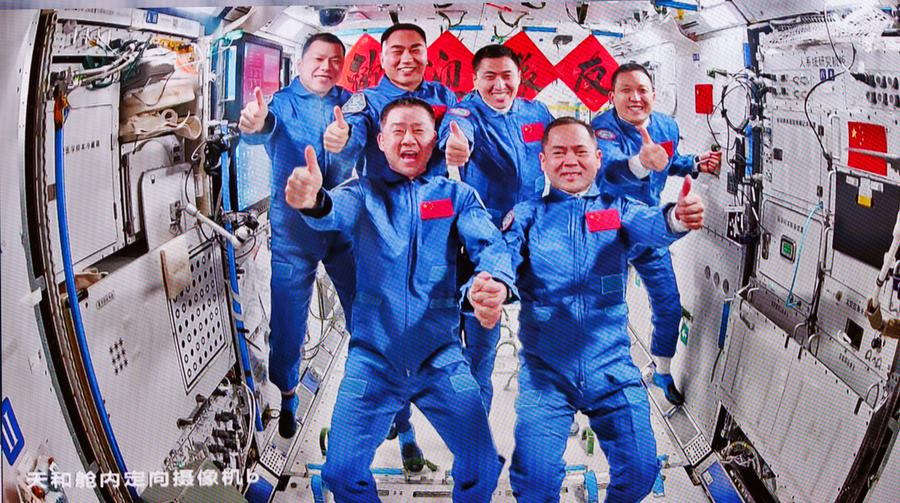

The impact of smart factories is already visible across many industries. In sectors like semiconductors, aerospace, advanced materials, and biopharmaceuticals, production has grown significantly as intelligent manufacturing becomes more common.

At the same time, research into next-generation technologies, including 6G, is laying the groundwork for future industrial connectivity.

China’s manufacturing is no longer just about machines. Data, integrated systems, and smarter processes are now shaping how factories operate. As smart factories scale up, they are not just faster — they are becoming fundamentally smarter, setting the stage for the next phase of industrial competitiveness.

Written by Ronnie Yu, Chart Design by Wang Di, additional reporting by CNS, HKCNA.

If you liked this article, why not read: What’s Next After 5G? China and GTI Launch 6G Test Platform

XxjpsgC000475_20250926_PEPFN0A001.jpg)